Cloud-based technology is a basic necessity for a company like high-tech manufacturer Flex.

Real time communications and cloud-based information exchange systems are commonplace in today’s expanding technological industrial paradigm, but for some companies those tools have become not just an afterthought or an add-on but a central part of doing business as they help bring together designers, customers and suppliers in a matter of minutes to make better decisions.

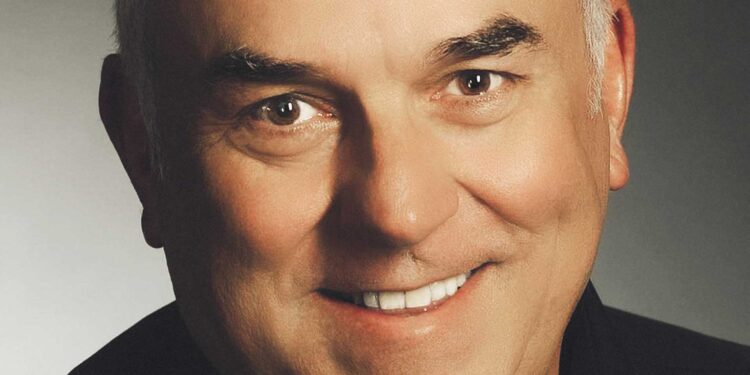

This is why a company like manufacturing developer Flex has put so much attention into developing its own in-house systems to make interactions both within and outside the company as efficient as possible, reducing time to market for customers’ solutions as well as minimizing the inevitable disruptions that can happen across the supply chain, its President of Global Operations, François Barbier, explains.

It becomes even more of a challenge for a company like Flex, which as a difference from many other manufacturers is not tied to any particular industry, but offers solutions ranging from encoders that have helped keep the Mars rover Curiosity working for over 5 years on the Red Planet, to the tracker systems increasing the effectiveness of solar energy arrays around the world, working across more than a dozen different industries with a range of core technologies.

As the world moves into what is called the Industry 4.0 revolution of virtual interactions and advanced robotics, “there is a lot going on in our business enabling us to become more digital, more reliant on technology, on the way we do our product and reach our customers. We can be more agile in the way we deploy our investments and much more aware of what’s going on in the entire supply chain,” Barbier adds.

SIMULATION, A GROWING TREND

One of the first things that come to Barbier’s mind as he describes how the company he has been a part of for over 15 years is adapting to change, is the fact that technology has advanced to a place in recent years in which a product can be seen an even tested way before going to production thanks to the quantum leaps in simulation technology.

“The world of what you can simulate when you are designing a product has changed a lot over the last few years. You have much more power to design by simulation and making sure that you are looking at objects —before they even exist— in a way that is very close to the final product,” he explains.

These efforts, he adds, need to be boosted in a company with over 25 design centers in several countries and 200,000 employees, and so Flex has made large advances in the way it interacts with customers to take them closer to the action and reduce the back-and-forth common to complex design projects, while making sure you are complying with the exacting specifications of parts that might end up ensuring the good health of a person or community.

“There are new tools for real-time interaction between customers and design teams,” he says. And those tools also help streamline the supply chain, the other side of the coin of that fastpaced industrial scenario.

ON TIME, ON PRICE, ON SPEC

As the company and its customers reach a finished design, they also need to start building a supply chain that will ensure delivery of parts and products in an affordable and efficient fashion. And in many cases, as Flex is the leader of many of the sectors in which it offers products, it has to build those chains and processes from the ground up. “We are creating our own way of working in the global ecosystems we are in.”

For Flex, Barbier explains, that entails effectively managing a 14,000-strong suppliers’ community delivering between 600,000 to 700,000 pieces per month.

There’s also a new way to work with your supply chain. When you design a product it includes different parts and components, and as you build your bill of materials you also need to build the supply chain that will be used to deliver products moving forward, and it will have to comply with several demands.

“For this to work you need the right kind of communications and visibility with your suppliers,” he adds, explaining that this area is one of the main beneficiaries of digital, real time communications, channeled through standardized processes to ensure that, wherever the client, the designer or the supplier is, they will receive timely and actionable data.

CRISIS MANAGEMENT ON THE FLY

Once these systems are in place, they can also help deal with the inevitable and sometimes devastating consequences of natural disasters or accidents, among others. “We invented a system based on a cloud repository and also real-time information that gathers all of those events and evaluates their potential impact on the supply chain.”

That fast-communicating network helped dampen the blow of the 2015 explosions on China’s industrial hub of Tianjin, that left some 173 people dead as several containers’ areas near the city’s harbor exploded causing a fire that lasted for several days and leaving billions of dollars in damages both to infrastructure and in lost goods.

“You need to know this information in a matter of seconds, minutes at the most, because you need to react if there is some kind of impact to your supply chain,” Barbier says.

The company has developed internally a sort of social-network of suppliers to achieve this effect and correlate almost immediately with suppliers to make on-the-spot decisions, he adds.