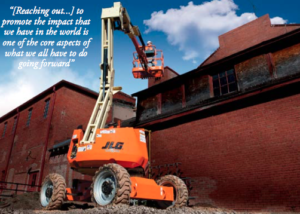

President Frank Nerenhausen sees confidence, safety, and desire for innovation at the heart of JLG.

JLG is a company that puts men and women to work safely at height.

As a leading manufacturer of lift equipment that enables men and women to do their jobs hundreds of feet in the air, JLG Industries has a fundamental commitment to quality and safety that is key to the ethos driving the company.

In the words of President Frank Nerenhausen, the company “instills confidence at height,” producing the tools that enable construction and maintenance workers to carry out otherwise extraordinarily di cult tasks. “We want the folks who use our machines every day to feel con dent when they go up one-hundred-and-eighty feet into a piece of aerial equipment,” he explains. “You can feel that stability in our machines.”

JLG was founded in McConnellsburg, Pennsylvania, in 1969 as a small metal fabrication business with a crew of just twenty workers. In 2006, the company was acquired by Oshkosh, and in 3Q17 reported an impressive net income of $128.6 million up from $84.2 million for the same period in FY2016.

Nerenhausen was appointed President of Oshkosh Corporation’s Access Segment, which includes both the JLG and JerrDan brands, in 2012, and immediately went to work to live up to the global reputation of both brands for quality and innovation.

Leading the company was a challenge that Nerenhausen was honored to take on. “As I began to understand the culture of JLG and its purpose in the world, I started to re ect on a broader vision for the company,” he said. “We’re a company that has a noble purpose. We put men and women to work safely at height around the world. We help move materials at job sites around the world.

“Our team members have an emotional connection to what we do and the purpose that we serve,” he added. “One of the things that our CEO [of Oshkosh], Wilson Jones, has really put an emphasis on is a people-first culture; building on our teams’ strengths, engaging them in the business, connecting them to our communities, and showing people that we do care.”

Embracing technology, guaranteeing quality

Given the constantly evolving technology propelling a business like aerial lift equipment, JLG looks not only to provide the safest machinery possible for its customers, but also constantly in- novate to meet the challenges of an increasingly demanding industry.

“We’ve actually launched some revolutionary products just in the past twelve months,” Nerenhausen explained, displaying a clear passion for the innovation side of the business. “We recently released our high-capacity telehandlers with SmartLoad technology, which is a bundle of three new technologies designed to increase operator confidence and optimize productivity; we launched the self-leveling chassis, which is the first of its kind and can operate on slopes and uneven terrain; and our SkyGuard enhanced control panel protection system which comes standard on nearly all JLG boom lifts.”

For Nerenhausen, the innovation side of the business involves listening to the very people that the company serves. “For example, there are a lot of issues happening with ladders right now; a lot of injuries, a lot of deaths,” he said. “We’re known for putting people up in the air as far as they can go, but there’s a real need to fulfill our mission at the lower end of the spectrum.

“We talked to folks in that niche of the industry and came across a group named Power Towers in the UK, which has been extraordinarily visionary in providing aerial access under six meters, and this is a real opportunity to supplant ladders in our industry.”

Support throughout a life cycle

Providing technical support throughout the life cycle of its products has become a key element of JLG’s business in recent years, and Nerenhausen views it as a major component of the company’s growth model, enabling even stronger and longer-lasting relationships with customers.

“As our customers become more sophisticated, they’re looking for more from their supply base,” he said. “That means going beyond producing the highest-quality, most productive machines in the world. Today, we need to provide the best support from the day the machine is delivered through to providing end-of-life solutions. What we’re looking at is the total cycle of the machine.”

According to Nerenhausen, this is another area that requires the spirit of innovation for which JLG Industries has become known. “We’re doing more in the area of telemetrics now, looking well down the road as we develop infrastructure to support connected machines and ultimately increase uptime for our customers,” he explained. “That’s where we’ll be putting our energy in the next three-to- ve years, and I think that will support growth not only in those activities but increase sales among our base machines as well.”

Supply chain confidence

Naturally, in a business where customers’ safety is par- amount, supply chain confidence is also crucial. JLG works with thousands of suppliers through its specially designated tactical and strategic teams around the world, and to achieve utmost efficiency, the company grants a certain level of autonomy to its operations in each region.

“We put a lot of emphasis on having the right leadership that can fulfill our core principles as a company, and we manage those metrics very closely from an efficiency standpoint,” Nerenhausen said. “But we also leave quite a bit of autonomy for those leaders on how to engage with customers and support them uniquely.

“A large portion of any machine is purchased components, so if you’re not good at buying the right materials at the right time and having them delivered to the right place, it’s a non-starter to be efficient in your business.

“We’ve developed a strong sense of collaboration between our regional leaders and our core functional groups here in McConnellsburg,” he added.

While JLG Industries is dedicated to producing machinery, Nerenhausen insists that the ability to find the right human resources is crucial to the company’s ongoing and future success.

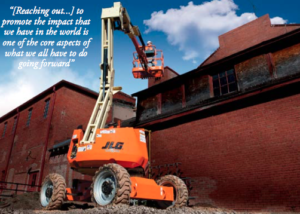

He has a strong philosophy of encouraging new talent from a young age, which he believes is a crucial element to the success not only of JLG, but of any ambitious company.

“If we don’t have the right expertise, if we don’t have folks that are passionate about our business, that’s probably the greatest obstacle to our success,” he said. “They key element we all face in the business community is finding that qualified talent.”

So reaching out, engaging, and connecting with people at the high school level, even at the middle school level, to promote the impact that we have in the world is one of the core aspects of what we all have to do going forward.”