Earlier this month, Apple CEO Tim Cook said he expected the majority of US-bound iPhones to be shipped from India.

Reviving US manufacturing has been a tentpole goal of Trump’s presidency. Within the first three months of his second term, he went on a tariff blitz, promising to impose levies on nearly every product made abroad in an effort to boost jobs in the US and rebalance what he saw as unfair practices by America’s trading partners.

But experts who spoke with CNN said making iPhones in the United States would upend the way Apple builds its most lucrative product. Moving iPhone production to the US would mean shifting away from countries like China and India that have the highly specialized workforce and skills needed to produce the millions of iPhones that Apple ships each year. The result could mean price hikes or design changes for the iPhone, some analysts estimate.

There’s also the question of whether there’s enough demand for factory jobs in America. Manufacturing has been on the decline in the United States, with only 8% of American workers holding jobs in that sector as of earlier this year compared to roughly 26% in 1970, according to the Bureau of Labor Statistics,

And a lot has changed since 1970.

Carolyn Lee, executive director of the Manufacturing Institute, previously told CNN that “the job has very much changed” and that modern manufacturing roles involve skills like coding and data analytics.

Apple said in February that it plans to invest $500 billion in growing its US footprint over the next four years, which will go towards boosting its research and development efforts, opening a new facility to manufacture servers to support its Apple Intelligence software features and launching a Detroit academy to teach companies about smart manufacturing techniques and AI. Trump has declared this investment – along with a $100 billion commitment from Taiwan-based chipmaker TSMC to expand in the US – a political win and a step towards onshoring more tech production.

But Apple’s academy will be for small-to medium-sized businesses, according to Apple’s press release, not training workers or building infrastructure to produce iPhones the way it is done in China or India.

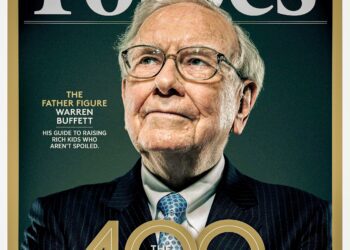

Cook has acknowledged the gap in labor required to produce iPhones in the US. Speaking at a Fortune Magazine event in 2017, he described the manufacturing environment in China as providing a combination of “craftsman” skills, “sophisticated robotics” and “the computer science world.”

“That intersection, which is very rare to find anywhere, that kind of skill, which is very important for our business because of the precision and quality level that we like,” he said.

Many of Apple’s suppliers are based in China, so transitioning to the US even just for assembly would mean shifting further away from critical components. Dan Ives, global head of technology research for Wedbush Securities, told CNN last month via email that an estimated 90% of the iPhone’s production process takes place in China, although he says that number is closer to 40% now that Apple has shifted more production to India. He has also estimated that making iPhones in the United States could triple the price of the device.

Apple is faced with a tough decision either way, says Forrester’s Chatterjee, despite Cook’smeeting with Trump last week and the $1 million donation he made to Trump’s inauguration, according to Axios.

“Because neither can you realistically, from an economic standpoint, bring production to the US, nor is it really tenable in this climate to say, ‘No, I won’t do that,’” he said. “So you’ve got to walk that fine line, that tightrope, for as long as you can.”