Peter C. Durette

Intertape Polymer Group Inc.

IPG (Intertape Polymer Group) has been rapidly expanding its packaging and protective solutions business and was honored with the 2024 “Large Enterprise Manufacturer of the Year” award from the National Association of Manufacturers’ Manufacturing Leadership Council (MLC) in recognition of its efforts in digital transformation and sustainability.

Upon assuming the role of CEO at Intertape Polymer Group (IPG) in November 2022, Peter Durette has endeavored to sustain the company’s impressive growth trajectory. He has focused on leveraging the ongoing e-commerce revolution and capitalizing on significant trends in sustainability, automation, and high-performance materials. Taking leadership shortly after the four-decade-old company was privatized by Clearlake Capital Group (“Clearlake”), based in Santa Monica, California, Durette has faced the challenge of achieving more than just cost reductions and profit increases.

“Over the past decade, the IPG team has more than doubled the size of our business and significantly expanded the range of solutions we offer to our customers,” said Durette. “We have established a robust platform for growth, featuring a diverse array of solutions aligned with key growth trends, a strong supply chain and operational footprint, an exceptional customer service model, and a talented team.”

“We have grown rapidly while maintaining a strong customer focus and entrepreneurial spirit, fostering a culture that has propelled us to significant success. This is what Clearlake recognized in IPG. They saw a great platform that was undervalued in the market, with the potential to drive significant growth and value creation in the coming years.”

“Nearly every manufacturing business needs to package its product to get it through the supply chain. So, you know, our whole business has the ability to impact the productivity of the operations of a lot of our partners to help them improve our business.”

To sustain growth, IPG and Clearlake have collaborated with the goal of further enhancing IPG’s portfolio of value-added solutions, fostering greater innovation, strengthening the supply chain, and accelerating productivity through operational excellence and investment in digital transformation.

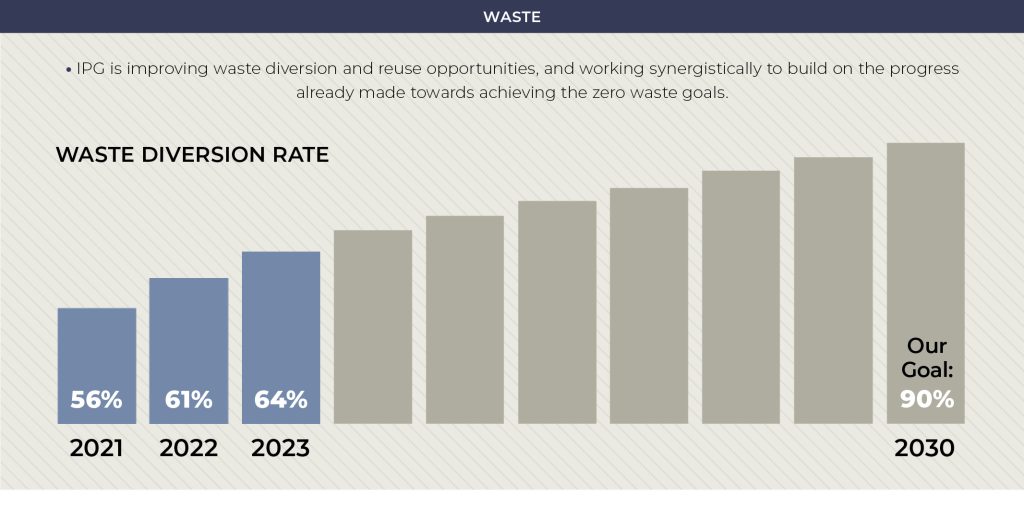

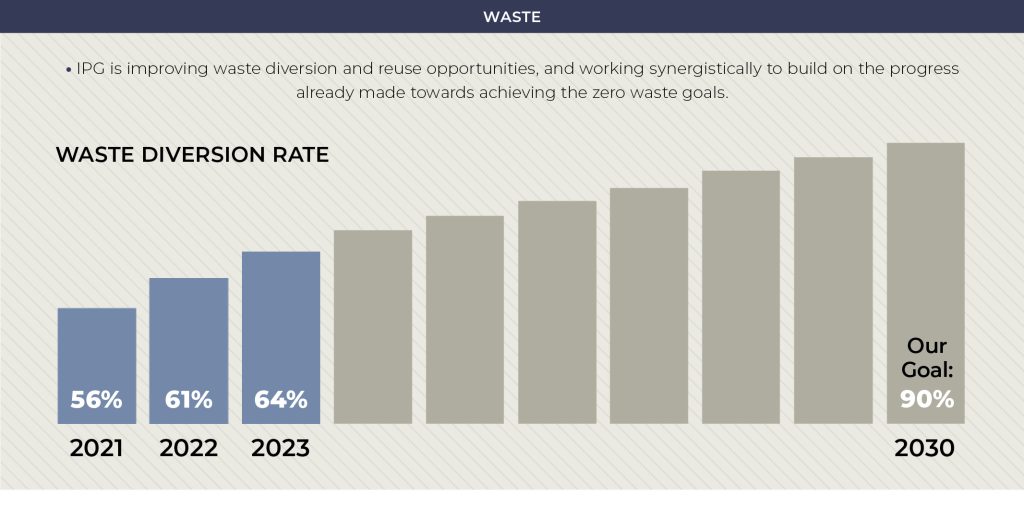

Environmental Sustainability

Durette has directed IPG’s employees to prioritize offering environmentally sensitive products and packaging systems that address clients’ operational needs and sustainability objectives.

To further emphasize that commitment, IPG has fully embraced the Cradle to Cradle Certified® Products Program, a comprehensive and rigorous sustainable product certification.

“One of the unique aspects of the Cradle to Cradle program is that it requires continuous improvement,” said Durette. “This means we must continually enhance our products’ sustainability over time, or we risk losing the certification. IPG leads the industry with over 15 unique product lines having achieved Cradle to Cradle certification at some level.”

“E-commerce has been a massive sea change for how products get to consumers.”

By integrating IPG’s sustainability goals with its product line, Durette believes that IPG is uniquely positioned to expand within the packaging market, distinguishing itself from competitors.

“We offer a vibrant set of solutions that stands out in the market,” said Durette. “Our distinctive combination of tapes, packaging materials, and packaging equipment forms a definitive product bundle that leverages our unique capabilities while meeting our customers’ needs.

“For instance,” Durette recalled, “We recently launched a new polyolefin shrink film, a thin, clear film used to wrap items like paper plates or frozen entrees, or for bundling multipacks at big box retailers. We were the first to introduce PCR shrink film with 45 percent recycled content, including 20 percent post-consumer recycled content. Achieving this in such a thin film is quite challenging,” he continued. “Additionally, the film is pre-qualified for the How2Recycle store drop-off label. This type of circular solution enables us to help our customers meet their sustainability goals throughout their entire supply chain.”

Innovation and New Products

“In the last 18 months, we have launched more new products and solutions than we did in the previous five years, and I foresee this trend continuing,” said Durette.

Looking ahead, Durette anticipates steady growth for the company. While business acquisitions have historically played a significant role in IPG’s expansion, he has set an ambitious organic annual growth target that exceeds the expected GDP growth in North America.

“As I mentioned, the company has doubled in size since the middle of the last decade. While part of that growth was inorganic, and we believe we have a robust platform to continue pursuing business acquisitions, I firmly believe that the business must establish a challenging yet attainable organic growth plan, leveraging innovation and customer relationships to capture market share.”

Boosting Performance with Data

To achieve its objectives, IPG employs the IPG Performance System (IPS), which uses lean six-sigma principles to engage team members in enhancing safety, quality, reliability, and cost efficiency. IPG also uses an X-matrix to set goals and translate medium- and long-term targets into immediate actions at its plants.

The data generated from these systems is integrated with investments in digital transformation tools to monitor and improve performance across various key areas.

Durette highlighted the production of water-activated tape as an example of how such data is driving improvements in productivity and performance.

“Consider the box you receive for an online order, sealed with printed fiber-based tape,” he said. “This product has been a significant growth driver for us due to the rise in e-commerce.”

“We have two factories that produce this tape,” he added. “One of them is a relatively new facility established towards the end of the last decade. We have seen a dramatic increase in productivity at this facility by leveraging digital transformation to enhance machine speeds and reduce downtime.”

Finding Ways to Say Yes

For Durette, several factors distinguish IPG in the marketplace.

“I perceive our company as having multiple dimensions,” he stated. “First, we offer a unique and diverse set of solutions that we bring to the market. Our product bundle, and what we can achieve with it, is distinct.”

“Secondly, we have established fantastic customer partnerships and relationships,” he continued. “These have been developed over a long period, and I believe we are regarded as a preferred and exceptional partner, collaborating on mutual business growth.”

“Our culture and team are highly agile and customer focused. We consistently look for ways to say ‘yes’ to our customers,” he added.

“We have invested in solutions that address key market needs: the growth of e-commerce, the demand for sustainable solutions, and the need for automation,” Durette said. “Combining all these elements creates a robust business system that sets us apart from our peers.”

Robustly Managing Risks

Durette is also aware that operational excellence involves managing the risks inherent in the global marketplace.

Maintaining a productive and reactive supply chain has been one of the company’s top achievements, according to Joe Tocci, IPG’s Senior Vice President of Global Sourcing and Supply Chain.

“We are extremely proud of the fact that we made it through COVID and all the disruptions that came along with it without ever once shutting a plant down because of a lack of raw materials,” Tocci said. “So, that’s the goal. The goal is always to be flexible enough so that we can continue to run your plants at a low cost and provide great service to our customers.”

“E-commerce is the biggest change that has happened to the packaging world and really how all our customers get their products to market and so continuing to drive innovation that makes that supply chain more effective, more efficient and more sustainable.”

Making that happen requires a close partnership with suppliers.

“Driving innovation requires strong collaboration with your supplier partners,” he said. “In many cases you need to change your inputs to be able to drive a more innovative solution, and in many cases your suppliers are the experts in those inputs.”

As a provider of automated packaging systems, solutions, and materials, IPG must consider not only its own supply chain but also how its operations integrate into the supply chains of its customers. Consequently, service extends beyond mere cost considerations.

“E-commerce has been a significant growth engine for us,” said Durette. “We collaborated with a machine manufacturer to launch what we call the pack station of the future, branded as E-CO Flex.”

This automated pack station enables one worker to perform tasks that previously required six workers in a busy e-commerce fulfillment site.

“It’s not just about reducing costs; it’s about addressing the challenge of finding workers for factory jobs these days,” Durette explained. “You have to find solutions that maximize worker productivity and help overcome the difficulties in sourcing skilled labor.”

Durette is enthusiastic about the direction in which IPG is heading and the potential of its future solutions and partnerships. “Packaging is an industry that people might not think about daily, but it impacts every consumer and business,” he said.

“If you had asked me at the beginning of my career whether I was destined to be a packaging executive, it wouldn’t have been in my career plan. However, once you get involved in this industry, it really gets in your blood. It’s incredibly exciting because it touches every single industry and business.”