Rizwan Ahmad

COO / Dialight

Rizwan Ahmad, COO of Dialight, shines the spotlight on the LED industry and explains how his company ensures that its customers, partners, and investors can access exceptionally safe, highly efficient, sustainable, and reliable products every day.

Dialight, founded in Brooklyn in 1938, originally produced panel lights for aircraft before the invention of the LED (in 1971) led the company to expand into the market. Since then, Dialight has established itself as a specialist in this field, revolutionizing the LED industry with innovative technologies and high-quality lighting solutions.

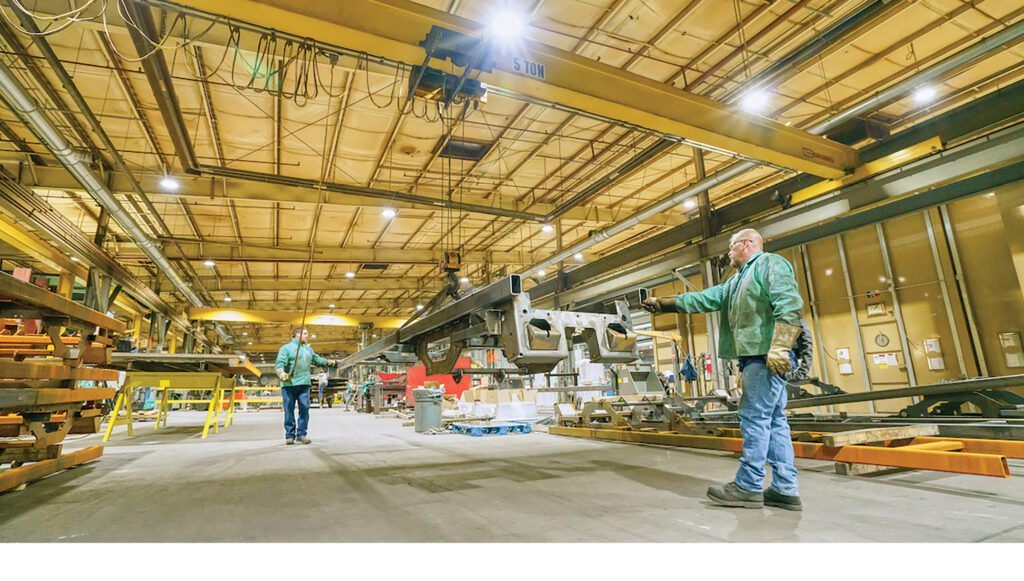

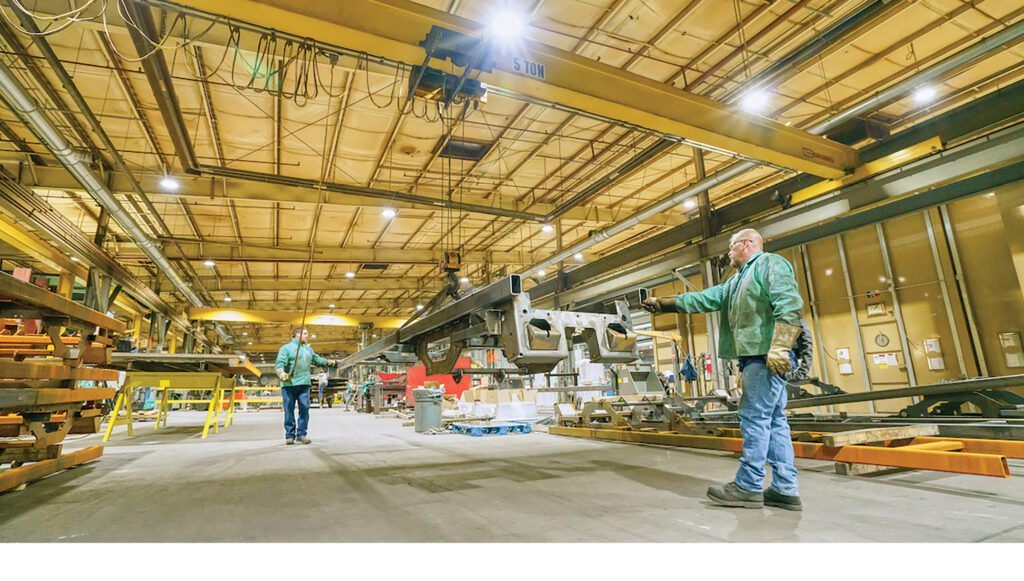

Today, Dialight primarily focuses on harsh and hazardous industrial applications and is well-known for its strict sustainability, safety, and operational efficiency standards. The company produces a range of industrial lighting fixtures, including high bays, area lights, linears, floodlights, wallpacks/bulkheads, streetlights, and IntelliLED control systems.

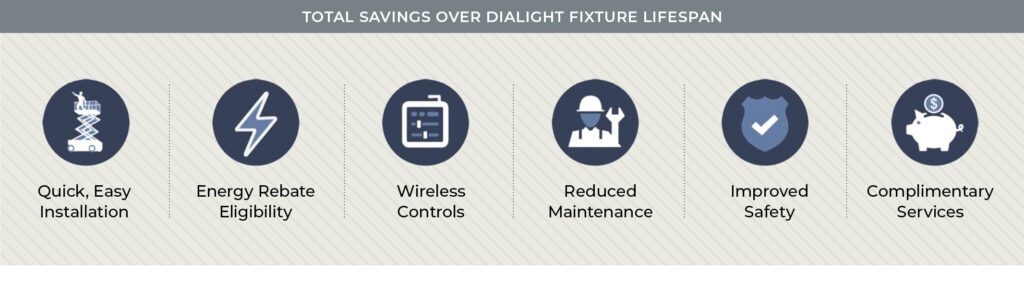

Dialight’s customers not only benefit from affordable, long-lasting LED technology; they also receive an industry-leading 10-year product warranty. Dialight maintains complete control over its technologies by developing all its products in-house, allowing it to stand out from competitors. The company’s strong reputation for cost-effectiveness and reliability positions it well for both short-term and long-term growth.

Leading With Passion and Experience

Rizwan Ahmad was already an experienced veteran at Dialight before taking on the role of Chief Operating Officer. Ahmad began his career at Dialight in 2001 as a Design Engineer. Over the years, he held various positions, including Engineering Management, General Management, Business Development, Product Management, and Head of Technology and Engineering. In 2024, he was appointed as Dialight’s COO during a crucial period when the company committed to an Operational Transformation and a comprehensive review of its end-to-end processes. His duty is to help the company streamline operations, reduce costs, and increase efficiency.

“Our products are known for their safety and reliability, and for setting the standard in their field. The fundamental reason behind that is that

we are different.”

Steering an Operational Transformation

Armed with decades of experience at Dialight, Ahmad approaches Operations with a comprehensive understanding of the company, its role as a leader in the LED industrial sector, and its significant potential to transform and grow.

One key focus in Dialight’s Operational Transformation, according to Ahmad, is simplifying the company’s products and processes. “Sometimes people think a light is a light and it should be a very simplistic market. Actually, it’s not. There are so many variations that the customer wants from you.”

“Operational efficiencies, if you sum it up, means that you are touching the whole life cycle of the product, whether it is current or whether you are bringing in new technology. You’re making sure you know that the end-to-end processes are optimized.” says Ahmad.

“My first goal in our Operational Transformation, is optimizing our end-to-end business.” Ahmad explains, “The second, is solving how we can continuously be the first in the market and the leader in bringing newer technology to the industrial LED sector.”

“My third goal involves new products. We are stepping into penetrating more applications with new products in the public sector, where more new products are needed.” One strong example of where Dialight is making significant operational improvements is the company’s policy to reduce the number of individual Stock Keeping Units (SKUs). This simplification has made a fundamental difference in manufacturing processes, saving time and money while the company still produces the same high-quality products for its customers.

“We are one of the few companies who are extremely meticulous and responsible regarding sustainability. We follow the ‘circular design approach’ where we begin with the material choice. We ask, what impact can this material have on the planet, such as the global warming potential?”

The Recipe for Success

Ahmad’s methodology as COO can be summarized into one simple equation; “Develop a clear strategy, connect people, establish discipline, and use a structured approach.” Ahmad firmly believes, “It’s a recipe that works—always.”

Ahmad strongly supports the company’s five pillars, applying them to his strategic Operations. The first pillar, “Winning Hearts and Minds,” focuses on engaging and exciting people and stakeholders – including shareholders and customers. The second pillar, “Sales Transformation,” aims to enhance support for the Sales team to ensure a steady flow of orders to company factories. The third pillar, “Operational Transformation,” involves streamlining and optimizing production capabilities. The fourth pillar, “Margin Improvement and Cash Generation,” promotes effective business operations to secure Dialight’s long-term future, and finally, the fifth pillar, “Creating a platform for future growth” focuses on building a path for the future.

Ahmad believes putting himself in his customers’ shoes is the best way to understand their goals and needs, he notes, “lighting can actually help customers reach their goals faster, and that’s where we excel.”

Dialight’s success is attributed to two main factors: “We have a powerful root-level relationship with our customers and partners,” and “Second only to our people, our products are our true differentiators. They have created a unique identity and brand for us.”

Endless Room for Growth

Ahmad points out that there are relatively few competitors in the LED industry. He believes that Dialight has a “clear competitive advantage” and differs from other lighting manufacturers. Ahmad explains that the company’s core business, LED lighting for Industries, operates in a market with huge potential for long-term structural growth – driven by sustainability and productivity.

“Statistics indicate that by 2025, only twenty percent of the market will have transitioned to LED technology,” he explains. The COO sees the company in an ideal position to capture the potential of an industrial market still largely unpenetrated by LED.

LED technology, being a semiconductor, “saves energy, requires less power, and can help reduce energy bills.” Ahmad knows that LED lighting represents the future. Considering that most lighting within the world’s industries is outdated and environmentally damaging, the LED market remains open and waiting for Dialight to continue to make waves.

As Dialight continues to grow, the company is gaining traction in a consistently profitable market with high margins. Looking ahead, the company aims to expand its presence in the North American market, where Ahmad admits, “In the US, it’s fair to say we are the leader.” “Our products are truly recognized,” Ahmad observes, “Living in the company for twenty-three years, there is one thing that I have never heard the other way around – we make the best products.”

“We design our products and we manufacture our products. For example, we do not buy off-the-shelf power supply. We design and manufacture our power supply in house – we also design and manufacture our optics in house.”

Viewing Sustainability as a Market Need

One significant advantage of LED lighting is that it is more efficient than traditional lighting, generating substantial electricity savings and reductions in emissions. Ahmad explains that the current LED market trends include a “strong focus on sustainability, energy savings, and cost reduction.” He is pleased that industries are moving in a direction where governments are providing rebates, incentives, and tax cuts.

Dialight is one of the few LED manufacturers that engages an independent firm to test its products using an Environmental Product Declaration (EPD). Ahmad notes, “On one hand, this demonstrates that we are a responsible company; on the other hand, we use that score to understand how we can improve our next product.”

Dialight carefully selects materials and components that ensure a longer lifespan, offering customers a life expectancy of 15 to 20 years for some products. “We provide replacement parts and design our products to make them easy to recycle.”

Dialight products also undergo “Accelerated Life Testing” for up to 140,000 hours, meaning the company simulates about 15 years of service during testing. Ahmad states that this is how Dialight demonstrates its commitment to reliability and quality, noting that “It really means that you are touching the whole life cycle of the product – not everyone offers this in today’s market.”

Looking Forward, Moving Forward

Dialight is moving forward with positive momentum and a clear strategy. Despite global markets remaining tough, the company maintains a strong stance on sustainability, with the company’s Net Zero Roadmap aiming to achieve net-zero greenhouse gas emissions by 2040.

Ahmad says, “The largest environmental impact comes from the emissions avoided by our customers, so the more efficient we can make our lights, the greater the benefit to society.” He concludes; “For us, it’s not just a blind journey in the direction of sustainability, we are a member of several organizations who advocate for advancements when it comes into the social and environmental agenda – and that truly set us apart.”